M14 Engine modification

to help reduce the possibility of Hydraulic Lock.

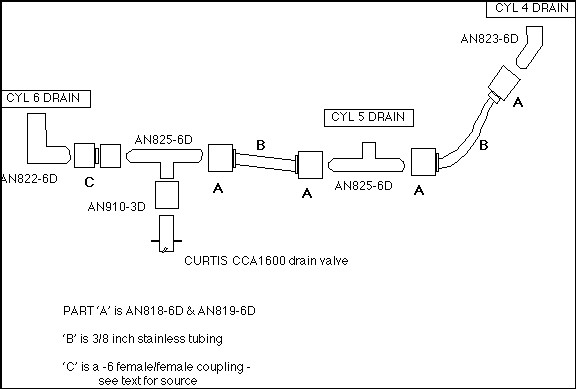

The fitting of an Intake Drain kit, to help reduce the accumulation of oil

in the lower cylinders, is very desirable. This sketch shows a simple intake

drain kit

for the M14 engine made from off the shelf AN fittings available from almost any

aircraft supply house. The total cost, (not including labor) is less than $100.

** Errata **

The part labeled AN910-3D in the above diagram should be AN910-2D

Parts List:

|

Qty |

Description |

|

4 |

AN818-6D Nuts |

|

4 |

AN819-6D Sleeve |

|

2 |

AN825-6D Flared

Tee |

|

1 |

AN822-6D 90°

elbow |

|

1 |

AN823-6D 45°

elbow |

|

1 |

AN910-2D

Coupling (Yes it is -2D NOT -6D) |

|

1 |

Curtis drain

valve (1/4" NPT) CCA1600 |

|

1 |

Female/Female

flared coupling * |

|

3' |

3/8" Stainless

steel tubing |

* Few aircraft supply companies stock this part but we have found it

in several racing car catalogs.

Our usual source is:

Pegasus Auto Racing Supplies at

1-(800)-688-6946.

They refer to it as a "Female swivel coupling, AN to AN".

Their part number is 3238-06

Procedure

- Remove all three drain plugs from the lower intake tubes.

- Drill a 7/16" dia. hole through the center of each plug.

- Tap the holes for a 1/4" NPT (tapered pipe thread).

- Screw an AN822 -6D (90° elbow) fitting into one of the

plugs and screw it into the intake tube of cylinder number 6. (7

o'clock, viewed from the front)

- Screw an AN825-6D (Tee) fitting into the second plug and

install it in the intake tube of cylinder number 5.

- Screw an AN823-6D (45° elbow) into the third drain plug and

install it into the intake tube of cylinder number 4.

- Using the proper flaring tool and two AN818/819-6D 'B'

nuts, make up a tube of the proper length to join the fittings from

cylinders 4 and 5.

- Turning to cylinder 6, screw the female/female union onto

the 90° elbow already installed in the intake tube. Into the other

side of the union, screw one arm of a Tee fitting with the side arm

facing downwards.

- Make up a second tube with AN818/819-6D fittings to run

from the other end of the Tee, under the front of the carburetor, to

the Tee fitting installed in cylinder 5.

- Screw an AN910-3D coupling onto the bottom of the Tee

fitting and into the other end of the coupling, fit the Curtis drain

valve.

- Finally, make the required cut-out in the cowling to allow

the drain valve to protrude just enough to operate.

Operation

After stopping the engine, open the drain valve and hang a container

on it to catch the oil. If you paint the container red, you will be less likely

to forget to remove it and to close the valve before your next flight!

This simple modification WILL NOT ELIMINATE HYDRAULIC LOCKs in the

engine, but it will make them less likely. It is still essential that the

propeller be rotated in the (in the normal (running) direction before each start

to check that there is no oil in the cylinder head.

Here are some pictures of the finished installation (on an Su31X)